Moving into the future

For the last three years, while the pandemic impacted the ability of our partners to visit our plants and see in person our offers, we have nonetheless been continuing to build on our strengths not just in the strategic expansion of our No-Frost platform, but in many other ways. Management, new staff training, a deepened design culture, more high-end product range, more digitalisation and automation, additional quality processes, evolved approaches to partner service and to sustainability all underpin Homa’s production vision: “Homa future production plants – smarter, faster, cleaner, brighter, and greener”. We demonstrate our care ethos in the recognition that a safe and pleasant working environment is essential for both staff and visitors, and the infrastructure surrounding the manufacturing site certainly ensures easy access to transportation, supermarkets, restaurants, and a bank. Onsite, the visitors’ experience has recently been enhanced with the addition of a special product showroom and upgraded meeting rooms.

New Product Showroom

Upgrated Meeting Room

Onsite, staff safety and comfort are taken extremely seriously. Annually, the month of June is dedicated to focused additional safety training and communication. Comfortable temperatures are maintained throughout thanks to a centralized cooling system in each factory. There is continuous treatment of Volatile Organic Compounds (VOC) to reduce harmful emissions, and fire sprinkler systems are in place. Overall investment in safety improvement equipment over the last 10 years has been over 5 million RMB.

The future of intelligent manufacturing: a virtual tour of Homa manufacturing

Click to explore Homa VR showroom:https://vr.homa.cn/

Visiting our manufacturing site, everywhere you will be struck by the high levels of digital management, with our mass production MES system, and state of the art automation. Moving into the sheet extrusion area, it is fascinating to watch the highly automated twin-screw extruder, with fully automatic control of feeding and forming, easy operation, and fast transformation, resulting in stable and uniform plate thickness and surface brightness greater than 80 nit. Our Side Panel Forming Machine is fully automatic, handling cutting, rolling, condenser pipe sticking and U-shell bending all in one line. Given the great need for flexibility in our business model, our best-in-class machinery enables us to shift quickly between different platforms. All this with high dimension accuracy and stable quality, with a tolerance within 0.015mm, and high productivity, with 160pcs per hour.

Sheet Extrusion Area

Side Panel Foaming Machine

Passing to the section dedicated to the production of vacuum formed cabinet liners, using machines constructed by our Italian partner Comi, you will be amazed by the speed and efficiency of the auxiliary hydraulic punching and shearing. At 115 units/hour, it is the fastest in the industry, providing a stable cabinet quality that also has the best-in-industry appearance.

Comi Inner Cabinet Thermo-suction

The automated high performance vacuum pump line will also impress you with its powerful vacuum pump working at 8 L/min. Vacuum timing stands at 15 minutes, with a vacuum degree of 12 Pa and an auto shut off system to retain the vacuum.

Automated High Performance Vacuum Pump Line

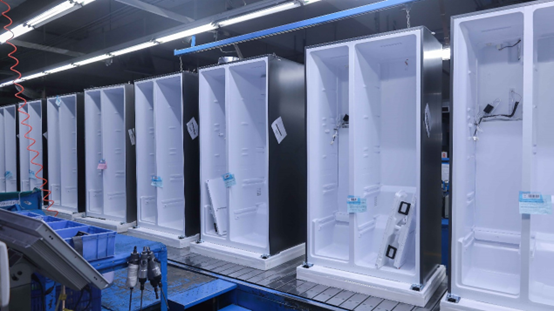

The cabinet assembly line conforms to the one-flow production mode of refrigerators, with line side auxiliary supporting automation equipment. The overall line speed is adjustable by frequency conversion, from 8-15s/m. Production capacity per shift is 3000 units.

Cabinet Assembly Line

On the dynamic cooling performance inspection line, you will once again have proof of our care for quality. Here the 45 minute fully computerized fast testing of the product provides high cooling detection efficiency and quick detection of abnormalities.

Dynamic Cooling Performance Inspection Line

Robots are always a pleasure to watch with their precise, ultra-efficient movements, and our carrying robot fulfils it role by reducing heavy labour for the workers while improving safety and handling efficiency, and reducing damage to the refrigerator as it is being moved.

Yaskawa Carrying Robot

A final stop in our virtual factory tour will take you to the auto sealing and packing line.

Here, the automatic Programmable Logic Controller (PLC) manages automatic box pushing, automatic binding, automatic code scanning into the warehouse, as well as entering the box data into the system for counting. Automatic pressing of the box top can provide a tightness of 75kg.

Auto Sealing and Packing Line

Auto Sealing and Packing Line

Partnering for value

Homa’s global scale and reach, the beautiful products we manufacture for our clients, our way of caring and of being part of our client’s team, and our belief that people and relationships are the key ingredients to our success: this is what defines us. This is what guides us in every business decision we take every day. Yes, like everyone else, we are in business to create shareholder value, but we know that this requires satisfying stakeholders, starting with our clients and their customers. Value is therefore a natural consequence of our ability to deliver on our unique and different proposition.We hope you have enjoyed this peek into the caring world of Homa, and we welcome the chance to get to know you better as you discover how we can add value to your business, through the diligence and imagination of our partnership possibilities!

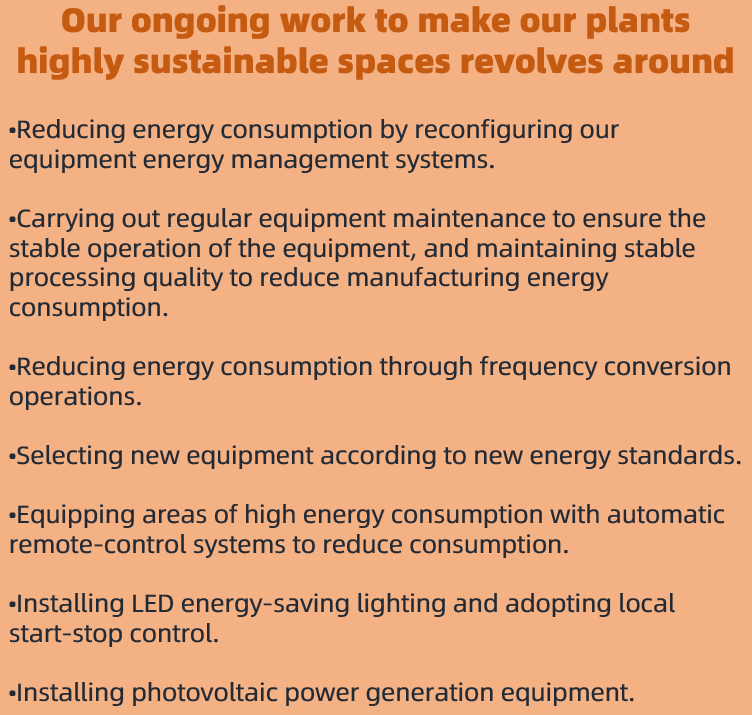

Sustainability in the factory

Having concluded our whistlestop virtual factory tour, it is important to come back to an acknowledgement of the fact that consumers around the globe are not just concerned about sustainability in terms of how much energy their appliances use, but also how sustainable the processes are in manufacturing those products, and they are less and less prepared to compromise. At Homa, we recognise how crucial this is, and you could say that the technology in our products and plants is conceived and validated under that perspective. In our vision, the purpose of technology is to serve the ideal of caring from a concrete, technical point of view.

Related Article:

*All data mentioned above is updated in March 2023

Copyright © Homa 2023

All rights reserved

.jpg?VGhlIFBlcmZlY3QgU2xvdC1pbijmraPnoa4pLmpwZw==)

.jpg?MTkyMHg3MjDvvIhkZXPvvIkuanBn)

.jpg?MTAyNHg3NDDvvIhkZXPvvIkuanBn)