An interview with Silvia Torretta, Studio Volpi Technology Director.

What is your definition of quality in refrigerators?

Let’s start with a few words on the basic and expected quality in today’s refrigerators. I would say that the first quality parameter of any home appliance is durability. When someone buys a refrigerator, they want to know that it will last reliably for a good number of years. For everyday use, the door must open well, the handle should be robust, the appliance must not make too much noise, in summer it needs to continue to keep food cold. Refrigerators today are not niche products – high performance standards are expected and taken for granted.

The quality of associated services and accessories is also an important factor. The consumer requires that replacement filters, shelves or baskets will be easily available and will not soon disappear through obsolescence.

And what are your ideas beyond these very basic elements of quality? Give us a more general overview of the idea of quality from the company’s perspective versus the consumer’s perception of quality?

I think the most interesting concept of quality today is where there may be a discrepancy between the company’s investment in quality in the production processes, and the way the quality of the finished product is perceived by the consumer. The company may invest in high quality, high cost materials and processes to produce what they consider to be a very high quality product, but many of these processes or materials may be invisible to the consumer, who then perceives that product to be of a similar quality to another in which the company has invested less. This discrepancy in perception becomes important when we connect it to the cost of production. For example, we have recently been working with a company whose specific role is the costing of products, evaluating quality efficiency in production compared to related costs. They break down the costs of a product and make visible the percentage invested in elements that have a direct effect on the consumer’s perceived quality, compared to the percentage of investment made in elements that are not perceived by the consumer. This investigation begins by looking at consumer pinpoints, using various sources such as consumer publications, online reviews and so on. From this they map out the strengths and weaknesses of the product, and then analyse its physical structure and break down the cost of its single components. They then weigh these costs against the consumer’s perceived quality of the product.

In the field of refrigerators, what are the elements of perceived quality? Where should we work to improve perceived quality?

One area I would focus on is the authenticity of materials. For example, the difference between the use of real metal and plastic with a metallic coating, gives a completely different touch sensation. The functionality may be exactly the same, but the genuine material will lead to a completely different consumer perception. So, anywhere there is the congruence between appearance and reality raises quality perception.

With the touchpoints where the user interacts with the product, attention to detail is important for raising quality perception, for example, on the handle where the user will experience various touch sensations, rather than the seals which are not really visible to the user, and with which they have no interaction. And of course, perceived quality involves all the senses, so for example in the case of a refrigerator, the noise of the motor, the noise the door makes when opened and its weight, are considerations. A user may not even be aware of such factors, but all the sense elements, conscious and unconscious, are important in building up a sensation of perceived quality. So overall, perceived quality derives from everything about a product that speaks of industrial craftsmanship and excellence in execution. For example, an unusual aesthetic detail that is not functional, but that demonstrates to the consumer that it was made with thought and care, can elevate the product above the average in quality perception.

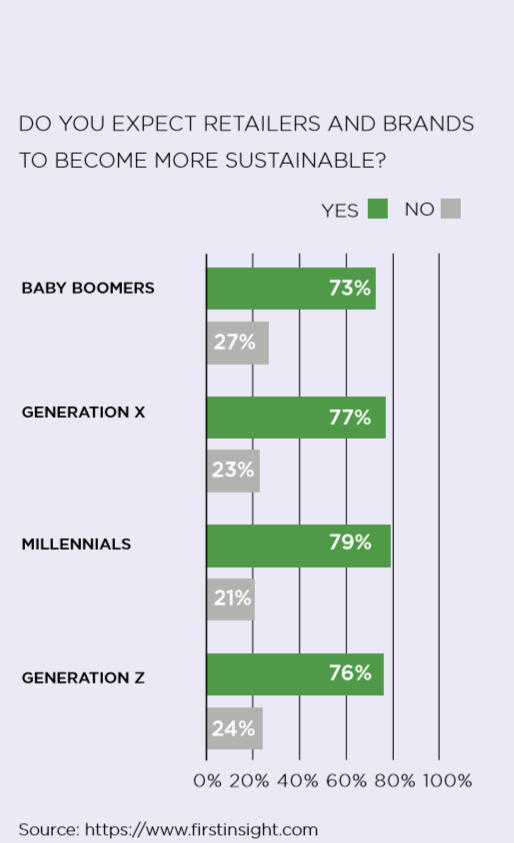

On the other hand, an interesting additional point regarding consumer sensibility today is that with growing sustainability awareness, the consumer can sometimes see extra embellishments of the product as a negative because of the environmental cost of their production. This is a change from a few years ago when across the board, add- ons, costly materials and showy finishes added value: now, yes, consumers will pay for high quality materials and design, but in a more visibly rational and environmentally sound way.

When thinking about this, we should be aware that in many cases, quality perception does not mean the elimination of small aesthetic errors such as slightly rough finishes or slight misalignments due to manufacturing tools and processes, but rather of finding ways to elegantly disguise the errors as a more cost-effective solution. In the refrigeration industry the cost of reducing errors to zero is not feasible or realistic.

However, companies work hard and invest in the best results possible. For example, I know that Homa has invested in high quality presses and builds-in the cost of more waste to ensure a neat and pleasing finish to the edges and corners of their refrigerators. For them, this is seen as a worthwhile investment for the higher quality perception achieved.

An interesting case in point around high levels of industrial craftsmanship and perceived quality are Dyson products, which ironically can also be considered through a negative lens. This contradiction is due to some peculiarities of their design. There are many elements of their design visible to the consumer that demonstrate high levels of craftsmanship and investment, with great attention to detail in comparison with an average product, while on the other hand, there are many internal elements of very high quality and cost that are not visible. It could be argued that the same functional result could be achieved by using cheaper components, but as Dyson occupies a notably high price point, they cannot take this path, so in their design process there is less focus on margins as they make their technological choices. However, some may argue that using such costly invisible products makes little economic sense.

Do you think there are cultural difference in perceived quality in different markets round the world?

Absolutely yes. It’s mainly an aesthetic difference related to familiarity with the different materials used, the shapes that are familiar. For example, if it is common to use a pan of a particular shape or material in one part of the world, people in that culture are more likely to give that shape or material a higher perceived quality. People will respond positively to the materials, processes, shapes that they are used to. So it’s important to be aware of differing cultural parameters and to adapt products to meet these for different markets.

Are there universal parameters of quality, including aesthetics?

Basically everything that appears as well thought-through communicates quality. Even if a product does not appeal very much to someone, if it demonstrates that there has been care in the process design and finish, the consumer perceives quality. On the other hand, elements such as misalignment, lack of harmony, variability in elements of a product over time, all impact universally across cultures on perceived quality.So apart from the basic expectations we discussed above, what do you think are the quality parameters of a refrigerator?

First, I would say quality is conferred by the elements of a product that do not change or become obsolete over time. So for example, any elements of interface or materials that are timeless are synonymous with quality.

Then technological standards are an important quality parameter. Take the example of mobile phones, we’re all used to taking the latest generation phones as the technological standard to measure everything against, even when looking at completely different sectors, so anything that falls below that technological standard is automatically seen as of lesser quality.

Once again, I would emphasis the importance of authenticity of materials. The consumer does not want to see that there is something of lesser quality behind what they see on the surface. For example, a visibly low-quality coating assuming the appearance of a higher quality material lowers quality perception even if the part is wholly functional.

Another element I think is important is the way the product works once you move beyond its appearance. Once the user starts to interact with the product, makes demands on it, it has to prove its quality through intuitiveness and ease of use, the impossibility of using it incorrectly. These elements derive from high-level design as an investment in true quality.

Does the industry constantly have to introduce advanced and innovative technological functions, or is it enough to have technology that ‘does the job’?

No, there isn’t a direct connection between the technological level and perceived quality. In fact when introducing new technologies, companies must remember that today people are used to rapid technological advances, and most are not early adaptors. There’s an awareness among consumers that in the early stages of new technological solutions there will be a phase of adaption and consolidation before they stabilise. Even with products employing very simple technology, it’s possible to evoke high levels of perceived quality.Can the topic of environment impact on quality? I’m thinking of a refrigerator that uses less energy, or environment sensitive production processes, or recyclable materials: are these elements of quality, or is that for the future?

Yes, I think all these factors are seen as a plus. They give the idea that the product design goes above and beyond simple functionality. In general, we are still in a phase where sustainability in industry is often just greenwashing and has little substance, so when a consumer does find real substance around environmental sustainability, they take note. Where a refrigerator truly uses less energy, this is a guarantee of quality because it’s verifiable.

In fact, the home appliance sector is perhaps more mature in this regard, because energy labelling and so on is already well established, whereas for most other products, even if they are innovative, environmental concerns tend to be secondary. When we see advanced environmental credentials on a product, we are aware that it has been developed with a 360° perspective as a choice, and not just because of regulatory requirements, even when that choice may involve higher design and production costs.

What are the tools, methodologies and processes that companies today have at their disposal to guarantee improved quality?

There are too many quality measurement tools to mention here, spanning those used in traceability of raw materials, through design to all the production processes. During production, quality interventions should be as simplified as possible, and not add further complications by generating reams of paper. For the consumer, they should result in a product that is easy to use, reducing variability and the chance of human error.What are future trends in quality?

One concrete trend that I see is the move to digitalisation which is also reaching into quality processes, for example the use of Artificial Intelligence and other advanced digital systems to do quality control work. This really does simplify and speed up processes, and lowers costs for the company by reducing the need to go back and correct errors.And in the future what will be perceived as quality?

I come back to the idea of perceived quality within a high level of industrialisation, where value is added by the consumer being very aware of the intellectual groundwork and expertise that has gone into the development of the product. For example, we have recently been looking at the refrigeration sector and the making of ice-cream.

This does not mean making it at the artisan level, but it still brings in added quality perception because there has been a deep dive into what ice-cream making involves, which characteristics of the process and end-product we should retain, really focusing on what the consumer wants and how to achieve what they perceive as quality.

So while of course a certain focus will always be toward the competitive needs of the market through constant controls of the industrialisation processes and balancing costs, this will be secondary to generating value through close examination and implementation of what consumers want.Are there any final points you would like to make about quality?

Well, I’d like to underline that for me quality always means a realistic compromise between a series of parameters such as the consumer’s perceived quality, the production cost, the environmental cost, the visible brand value. Different parties have different expectations. Procurement will want to pay the minimum for materials and receive those materials rapidly and cost-effectively. Designers may want to use costly materials and parts while these may not add value for the brand in increased consumer quality perception. Manufacturers have to balance the cost of meeting regulatory environment requirements with production costs. The consumer will want an efficient product that lasts, looks good and meets their price expectations. All these elements and more must be balanced for a relative and realistic quality solution.

Copyright © Homa2023

Allrights reserved

.jpg?VGhlIFBlcmZlY3QgU2xvdC1pbijmraPnoa4pLmpwZw==)

.jpg?MTkyMHg3MjDvvIhkZXPvvIkuanBn)

.jpg?MTAyNHg3NDDvvIhkZXPvvIkuanBn)