This is the second part of our interview with Fabrizio Longoni, directorgeneral of Centro di Coordinamento RAEE.

Fabrizio Longoni, director general of CDC

How does easy-disassembly of the various components affect the recyclability of a product?

The ultimate goal of the industrial recycling phase is to obtain usable, homogeneous raw-materials, so the easier it is to separate them the better. For what concerns cooling appliances, there are some operations that need to be performed in the first place, starting with making the products “safe”. In particular the compressor and the serpentine must be emptied of all the oil and gases and separated from the rest of the appliance, which is anyway made of a multiplicity of components. The electronics alone are quite intricate and made up of a myriad of elements. The insulation represents a further problem, as it adheres quite strongly to the panels, and contains different types of gases, including pentane, which is highly flammable. Expanding polyurethane with gases such as pentane is easy and cheap when producing the appliance, but it becomes an issue when it comes to its dismantling. Even modern day state-of-the-art insulation represented by VIP Vacuum Insulated Panels do pose some problems for their core is made of either glass fibre or silica. Working in a standardised environment with standardised products and procedures is relatively easy and safe, while having to do with a variety of products of all shapes, ages, and production methods is a completely different ball game.

What about LED lighting, does that make a difference?

It certainly does, but less in terms of energy savings than on the health and safety front which heavily impacts the cost of disposal. Traditional light bulbs contain tungsten, which prevents them from being easily recycled as glass, since it will seriously damage glass foundry furnaces. Even energy-saving fluorescent lights pose a problem since they produce light through a chemical reaction involving mercury vapour. These can represent a serious contamination and health hazard in the disassembly phase. LED lights, in that sense, are much easier to treat, without any risk, and therefore are cheaper to recycle.

What happens to the electronics?

Nowadays there’s an increasing quantity of electronic components in our appliances. A typical motherboard is made up of a very large number of elements, each in very small quantities. These components are simply set aside and dealt with by specialised facilities. There are a few in Europe, but Japan is highly specialised in this field and is literally importing scrap electronic components to extract the rare and valuable elements they contain and re-inject them in the production cycle.

Cooling appliances also contain gases…

That’s correct, and similarly to plastic, we have developed and used many types of gases over time. Recycling facilities need to be prepared and equipped to deal with each possible kind of product, some are not legal to use in today’s appliances, with the objective to avoid contamination of the environment. At the moment, the geographical areas with the highest quantities of “old” gases in their discarded appliances are Northern European countries or regions with cold climates. Southern Europe or warmer regions have already disposed of almost an entire generation of products containing such gases since cooling appliances tend to have a shorter lifespan in hot climates. Let’s also remember that gases are not only contained in the compressor-serpentine system, but also in the insulating materials, from which they need to be “squeezed out”.

How much of the recycled materials end up in new appliances?

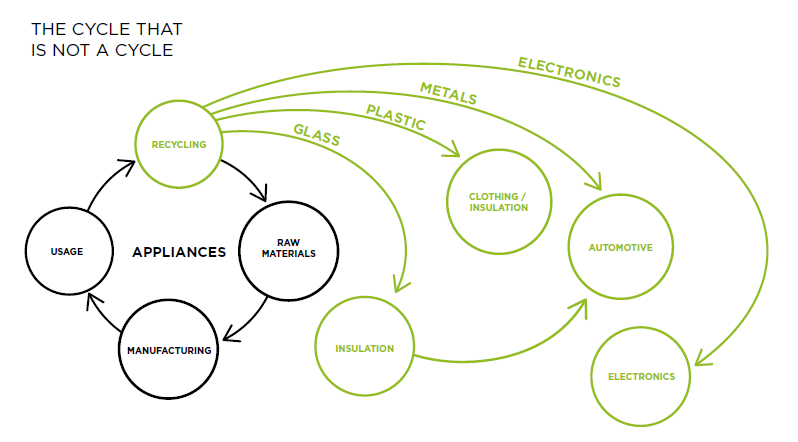

Apart from steel and copper, which can subsequently also be employed in any industry as a pure-grade material, not much, really, since the industry tends to work on highly standardised processes that depend on standardised raw-materials. But that’s not the point, since the purpose of recycling is that these materials do have a new life of some sort. If glass coming from the shelves of a refrigerator cannot be employed in the same role again, perhaps because of unsightly impurities, it may end up as glass fibre in some kind of insulation. Similarly, the shiny transparent plastic of balconies, the immaculate inner lining of the cavity, may find a new life in pile garments or even as an appliance’s chassis.How much does it cost to recycle a fridge?

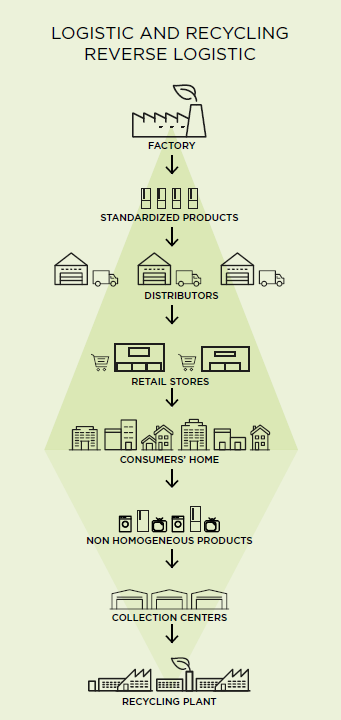

It’s hard to tell precisely since we are dealing with an immense variety of models, sizes, shapes, materials and technologies. The current average figure agreed upon in the industry is around 4% of the cost of production, if we don’t consider collection costs from consumer homes to centralised collection points. Even so, logistics still represents the largest part of such cost. With respect to the production, distribution and delivery phases in a product’s lifecycle, dismantling and recycling demand a “reverse logistics” approach, whereas, instead of shipping a multitude of products from one single facility to a number of distributors, then to retailers and eventually to consumers, here we are doing the exact contrary: we are collecting products from a multitude of locations and shipping them to a single facility. These products are not even the same size or weight, so you have no way of optimising your transport, hence the heavy impact on costs.

As we kiss good bye to our trusted double-door on its way to a new life, we might be saddened by the fact that we probably won’t see it again in our kitchens, but comforted by learning that, in a not-so-distant future, we might be wearing it instead, or keep warm thanks to it, or even drive it! What’s important is that it won’t end up in a landfill, our oceans or even worse, our atmosphere. In that, designers have a very important role to play in making sure our appliances are ever more recyclable and kind to our planet.

Related Article:<The Multiple Reincarnations of the Domestic Refrigerator: Interview with Fabrizio Longoni Part.1>

.jpg?VGhlIFBlcmZlY3QgU2xvdC1pbijmraPnoa4pLmpwZw==)

.jpg?MTkyMHg3MjDvvIhkZXPvvIkuanBn)

.jpg?MTAyNHg3NDDvvIhkZXPvvIkuanBn)