My aim is to create flexible and functional architecture that responds to the changing needs.

——Richard Rogers

01 FOREWORD

As the most automated factory in Homa's history, Homa No-frost District focuses on the production of large high-end No-frost refrigerators. This is expected to expand Homa's annual production capacity to a new height of 16 million units, better meeting the demands of the global market. By incorporating advanced design concepts, Homa aims to present a unique answer in terms of intelligence, sustainability, and human care.

02 PROJECT INTRODUCTION

Though Homa's previous factories used internationally advanced and domestically leading machines, our design ideas focused more on efficiency while not fully considering aesthetics due to the limitations of factory space and production line layout.

So we introduced CMCU Engineering Co., Ltd., a company has extensive engineering design experience in the design and construction of home appliance industry parks, to carry out high-level design planning for the Homa No-frost District.

CMCU‘s design team is familiar with the latest processes in the home appliance industry and has significant advantages in integrated engineering design,undertaken the design of industrial parks for well-known manufactures such as Haier, Midea, Hisense, TCL and Xiaomi. Three of their designed factories have been recognized as "Lighthouse Network" by the WEF (World Economic Forum) and McKinsey & Company.

By combining Homa’s history of development from scratch, the design team integrated Homa‘s long-standing thinking on building a high-end export brand and its aesthetic accumulation in industrial design into the construction of the new factory. Then we now have a contemporary industrial complex settled that perfectly blends efficiency and aesthetics with practicality and human care.

03 PLANNING CONCEPT

Homa No-frost District covers an area of 72,000 ㎡ including 3 Production Areas, a 16,000 ㎡ Smart Logistic Centre, a 15-floor Living Campus and other related supporting facilities, with an annual production capacity of 3 million high-end No-frost refrigerators, and a warehouse of finished products that can store up to 170,000 units. The entire industrial complex can provide more than 2,500 jobs. The Living Campus is also equipped with a garden, entertaining room, library, basketball court and other facilities, realising a one-stop Work-Life-Play package.

LEAN, GREEN, SMART & CARE are the key words we set at the beginning of the project design. With this clear mind, efficiency, sustainability and safety management have been consistently incorporated into the design and construction.

Function First: The industrial complex is designed to prioritise efficiency. The production area adopts a highly efficient production line layout. Smart Logistics Centre near the warehouse is enable deploy rapid storage and deliver of products.Human-centric: our design gives a full consideration to our employees, providing sufficient entertaining facilities, such as gym,basketball court, library,cafe...enable to meet all people’s needs.

Sustainability: Low-carbon design is widely adopted, with solar panel installation design, EV charger park, LED lighting and recycling centre from the very beginning of the design.

Smart Management: Everything is done in an orderly manner within the industrial complex under digitalized management system. From the purchasing of production parts to assembly and final logistics,everything will just fine.

04 DESIGN STORY-COLOUR

●Warm Connection: The factory‘s exterior design cleverly blends cool grey with warm accents. The grey reflects Homa’s rigorous, efficient production, creating a calm atmosphere. Warm colors in the passageway guide eyes and steps, enhancing connectivity of different production areas and adding layers and movement to the construction. With the distinctive orange shade,passageway symbolizes more than just physical connection, but making the complex a living, breathing entity and reflecting Homa’s interactions to the world.The facade features vertical strip windows and natural stone paint texture materials to highlight the technological sense. The combination of classic separate facade and modern craftsmanship gives the building a profound and timeless quality, not only making it more iconic but also maintaining a unified urban form while enriching its architectural image.

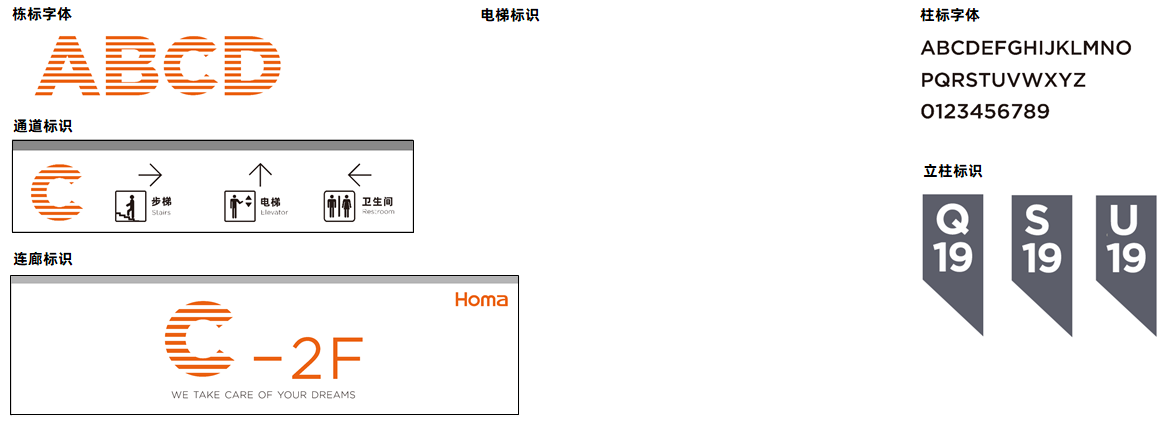

●Clear VI & Mapping Design: The visual guidance design inside and outside the factory is also in distinctive orange. These eye-catching colours not only delineate areas and direct movement, but also add a vibrant and contemporary feel to the space, enhancing its usability.

●SUNLIGHT: Compared to our previous factories, we have increased the use and size of glass windows on the exterior, complemented by courtyards naturally divided by passageways. This allows more natural light to enter the factory, ensuring indoor lighting and visibility while giving the exterior varied visual effects under different lighting conditions. Sunlight through the glass casts dappled shadows on the interior walls and floors, bringing softness and warmth to the cold industrial space. More natural light not only means lower energy consumption but also reflects our commitment to sustainability.

●INNER LIGHT: In areas where natural light is insufficient, our custom-designed artificial lighting system provides a solution. By considering the layout of production equipment and operational processes, we have ensured even light distribution by adjusting the height and angle of the lighting fixtures. This ensures that every work area is well-lighted, enhancing the sense of depth and dynamism in the space.

●Advanced Signage: Since arbors are widely distributed in Guangdong, this project incorporates the post-processing of the factory exterior and the design of the signage within the concept of the arbor forest, using natural lines as a reference for the signage design. These lines not only represent the local natural environment but also reflect our human-centric approach and commitment to sustainable development.

The internal plant signage of the entire factory is based on the modern international airport orientation system, with clear numbering management for every entrance, exit, lift, lift cage, and column in the factory. Large, clear signages allow personnel inside and outside to quickly and accurately locate specific places, areas and paths.

05 SUMMARY

The design of Homa No-frost District fully embodies fully embodies the combination of function and aesthetics. Both the concept of sustainable development is demonstrated through the introduction of solar panels, green environments and a usage of natural light, while the collision of cold and warm colours gives the building a unique visual effect, forming an industrial complex where modern industrial style and humanistic care combined. It not only enhances the overall image of the factory, but also create an efficient, comfortable and environmentally friendly working environment for our employees. Homa No-frost District is a firm commitment to our future development while showing our core value FOOD PRESERVATION, DESIGN & CARE.

Click here to get more information: OPENING OUR NEW CHAPTER OF SMART MANUFACTURING

Copyright © Homa 2024

All rights reserved

.jpg?VGhlIFBlcmZlY3QgU2xvdC1pbijmraPnoa4pLmpwZw==)

.jpg?MTkyMHg3MjDvvIhkZXPvvIkuanBn)

.jpg?MTAyNHg3NDDvvIhkZXPvvIkuanBn)