Put simply, sustainable packaging is the sourcing, development, and use of packaging solutions that have minimal environmental impact.

Ask the older generation about the packaging they remember from their youth and you might be surprised. Cotton or paper bags, sometimes even newspaper, to carry loose produce, simple cardboard boxes for deliveries which were then recycled to pack supermarket shopping, no plastic wrapping or bags, and sheets of padded cotton to protect large items for transportation.

But in the past 50 years, faster product cycles, global supply chains, new materials, all driven by different and evolving consumer expectations have brought about the mass use of industrial packaging, from tightly wrapped fruit in supermarkets to the shipment of large domestic white goods.

But alongside the meteoric growth in the global movement of products needing to arrive protected and undamaged, there is now rising concern about the toll that unsustainable packaging, particularly single-use plastics, is taking on the planet.

According to the "Plastic Waste Makers Index," published by the Australia-based philanthropic Minderoo Foundation, in 2019, 130 million metric tons of single-use plastics were thrown away around the world, with 35% burned, 31% buried in managed landfills and 19% dumped directly on land or into the ocean.

These figures make scary reading, and unsurprisingly growing numbers of concerned consumers are pressurising legislators and agencies, manufacturers and suppliers, to find others solutions, without losing the undoubted benefits of well-packaged products

“An average consumer in the western world will handle more than 50 packaged products / items every day.” (GWP Group)

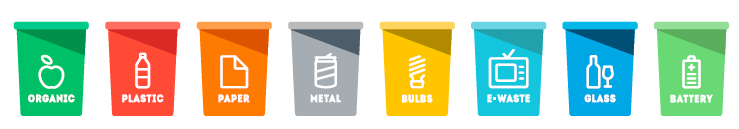

Reuse, reduce and recycle – the circular economy

On the frontline of everyday life, campaigns encourage the consumer to buy unpackaged products where possible, use less plastic in the home for food storage, use reusable coffee cups and water bottles, and drink tap or filtered water to avoid single use plastic bottles.For industrial packaging, much research is taking place to create lighter materials to make transport more efficient and sustainable by reducing weight and thus reducing the carbon footprint of each journey. Attention is also paid in designing the shape of specific packages, thus maximising space to achieve full loads.

There are certainly still many obstacles to overcome. For example, the transportation of fragile goods such as large domestic appliances needs very strong and resilient packaging to protect against impact, vibration and compressive stresses. The most commonly used packaging for this purpose is expanded polystyrene, which can be recovered to be crushed and reused, but currently the recovery rate is low, resulting in the potential for land and ocean pollution. Against the cost to the planet of such pollution, under present circumstances it’s necessary to offset the costs that would be involved in less effective packaging, resulting in damaged products and wasted journeys, a whole chain of carbon emissions for nothing.

New ways to pack

There are many exciting new biodegradable packaging solutions coming along:

Plant-based: this is made from biological sources — everything from mushrooms and seaweed to corn and food waste.

Edible: this also comes from biological sources, going one step further by being safe to eat!

Plantable: these have seeds embedded in them, a fun idea for customers. They work well for containing small, lightweight items such as cosmetics or jewellery, and can also be used as fillers or product wraps.

Compostable and biodegradable plastic alternatives: these are made out of materials that can be composted at home and commercially. They’re often made from plant-based polymer that can break down in compost.

“The basic idea of packaging is not just to appeal to the consumer, but at the same time ensure that the content inside is intact. Sustainable packaging materials are made up of products that are recyclable and reusable, but they may not be as efficient as plastic and other thicker packaging materials that ensure product safety” (infiniti research)

Simplifying and clarifying

Work towards creating monotype plastic bottles for cosmetics and household liquids is urgently underway, as currently the presence of different types of plastic in the bottle itself, the lid and the label makes recycling difficult.

Manufacturers and distributors usually have clearly defined responsibilities for the recycling and disposal of packaging, but clear labelling of packaging for consumers on to how to recycle is an important area for improvement, and depends on interventions by legislators.

So while we rely on our governments, scientists and agencies to push hard and fast for important lasting solutions to these complex problems, let’s keep the following in mind for our own day to day ’packaging’ lives…

.jpg?VGhlIFBlcmZlY3QgU2xvdC1pbijmraPnoa4pLmpwZw==)

.jpg?MTkyMHg3MjDvvIhkZXPvvIkuanBn)

.jpg?MTAyNHg3NDDvvIhkZXPvvIkuanBn)